List of Products

In addition to the B Series and the both-end hydroxyl group-terminated G Series of butadiene homopolymers, and the hydrogenated polymers of these base resins, we have a range of various derivative products to meet users' needs.

The physical properties are shown as representative values.

Base Resins

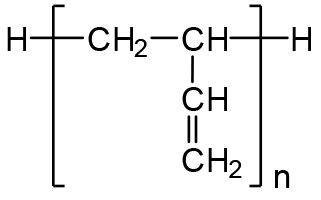

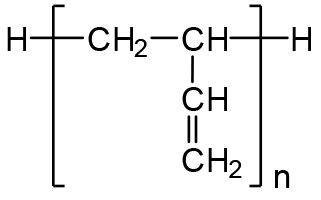

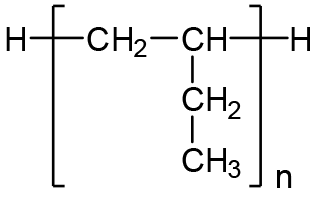

B Series / 1,2-Polybutadiene Homopolymer

The B Series is a homopolymer of butadiene. It has excellent plasticity as a property-modifying additive for various plastic resins and compositions. With a 1,2-vinyl structure above 85%, this series provides high reactivity to thermal or light stimulation. Also, its characteristic structure gives it a low dielectric constant property which makes it ideal as an electrical or electronic material. There are three grades ? B-1000, B-2000, and B-3000 ? classified according to the difference in mean molecular weight. Viscosity, glass transition temperature and other properties vary according to the molecular weight, providing options for selection according to the desired properties.

| Products |

Number-average molecular weight |

Microstructure (%) |

Viscosity (Poise/45°C) |

Hydroxyl value (KOHmg/g) |

Specific gravity

(25°C/4°C) |

| 1,2-vinyl |

trans-1,4 |

| B-1000 |

1200 |

85 and above |

15 and below |

10 |

- |

0.86 |

| B-2000 |

2100 |

90 and above |

10 and below |

62 |

- |

0.86 |

| B-3000 |

3200 |

90 and above |

10 and below |

210 |

- |

0.87 |

Principal Uses

Resin modifiers, plasticizers, coagents, photomechanical materials, adhesives, water-based paints, electrodeposition paints, electrical insulating materials, sintering binders

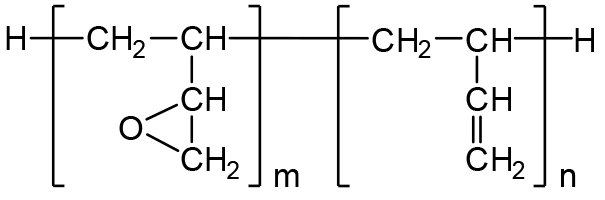

Structural Formula

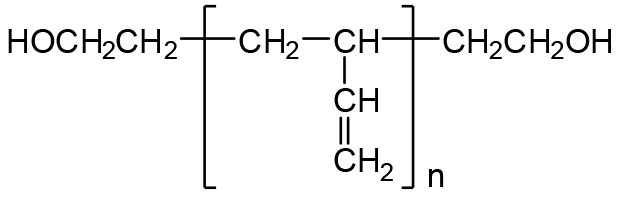

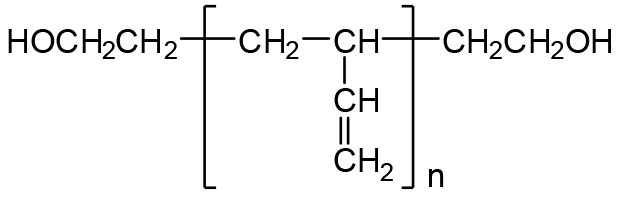

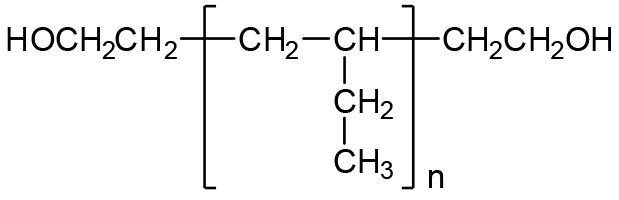

G Series / Both-end Hydroxyl Group-terminated Polybutadiene

The G Series is a both-end hydroxyl group-terminated polybutadiene. As with the B Series, the structure of the main chain is composed predominately of 1,2-vinyl structure, but because it has hydroxyl groups at both ends, it can be developed for different uses. With the hydroxyl groups as the active sites, the G Series can be used as a diol component of polyester, polyurethane, and other polymers.

| Products |

Number-average molecular weight |

Microstructure (%) |

Viscosity (Poise/45°C) |

Hydroxyl value (KOHmg/g) |

Specific gravity (25°C/4°C) |

| 1,2-vinyl |

trans-1,4 |

| G-1000 |

1400 |

85 and above |

15 and below |

75 |

68~78 |

0.88 |

| G-2000 |

1900 |

85 and above |

15 and below |

135 |

35~55 |

0.88 |

| G-3000 |

3000 |

90 and above |

10 and below |

310 |

27 and above |

0.88 |

Principal Uses

Resin modifiers, urethane resins (paints, adhesives, coating agents), deposition primers, parting agents, electrical insulating agents, TPU elastomers

Structural Formula

Hydrogenated Resins

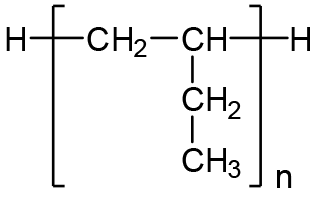

BI Series / Hydrogenated Polybutadiene

The BI Series is a hydrogenated polybutadiene. This series has excellent long-term chemical stability in terms of light and weather resistance, etc.

| Products |

Number-average molecular weight |

Terminal functional group |

Iodine value (Ig/100g) |

Viscosity (Poise/45°C) |

Hydroxyl value (KOHmg/g) |

Specific gravity (25°C/4°C) |

| BI-2000 |

2200 |

- |

21 and below |

50~100 |

- |

0.86 |

| BI-3000 |

3300 |

- |

21 and below |

100~300 |

- |

0.87 |

Principal Uses

Resin modifiers, plasticizers, adhesives, paints, electrical insulating materials, cast resins

Structural Formula

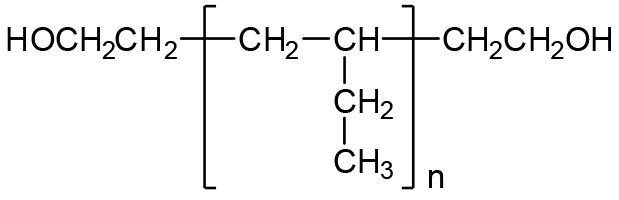

GI Series / Both-end Hydroxyl Group-terminated Hydrogenated Polybutadiene

The GI Series is a hydrogenated polybutadiene which has hydroxyl groups on both ends. In addition to chemical stability, the compound has hydroxyl groups on both ends as the active sites.

| Products |

Number-average molecular weight |

Iodine value (Ig/100g) |

Viscosity (Poise/45°C) |

Hydroxyl value (KOHmg/g) |

Specific gravity (25°C/4°C) |

| GI-1000 |

1500 |

21 and below |

80~140 |

60~75 |

0.88 |

| GI-2000 |

2000 |

21 and below |

120~250 |

40~55 |

0.88 |

| GI-3000 |

3100 |

21 and below |

250~450 |

25~35 |

0.88 |

Principal Uses

Resin modifiers, urethane resins (paints, adhesives, coating agents), electrical insulating materials, TPU elastomers, cast resins

Structural Formula

Modified Resins

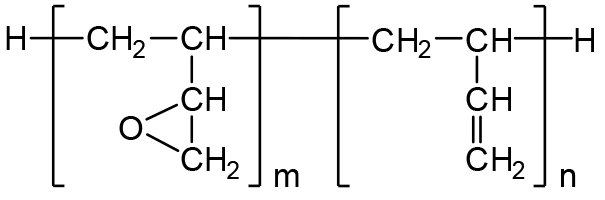

JP Series / Epoxidized Polybutadiene

The JP Series is an epoxidized polybutadiene formed by introducing an epoxy group through oxidation of the vinyl group of 1,2-polybutadiene. It is used as a copolymer component of epoxy resin compositions. Because the JP Series has only partial epoxy introduction, it retains the plasticity and electrical properties derived from its 1,2-vinyl structure, which produces a setting material with characteristics different from those of general-purpose epoxy resins.

| Products |

Epoxy-equivalent weight (g/eq) |

Viscosity (Poise/45°C) |

| JP-100 |

190~210 |

220 |

| JP-200 |

210~240 |

1000 |

Principal Uses

Resin modifiers, adhesives, paints, encapsulants, epoxy curing

Structural Formula

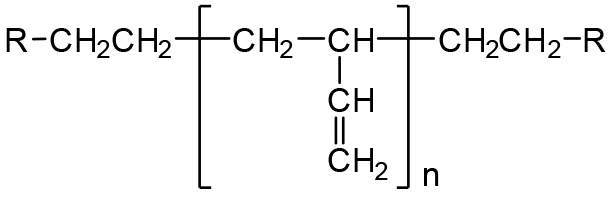

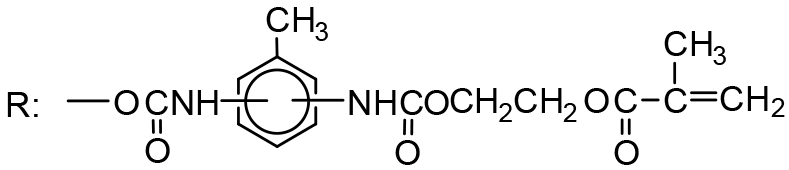

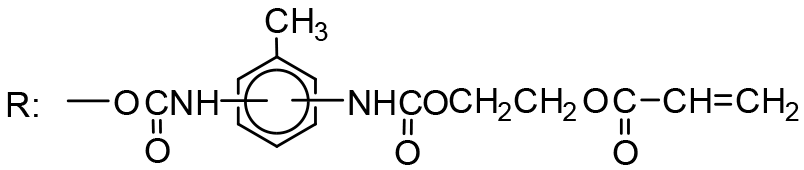

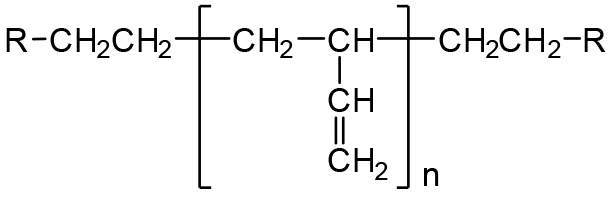

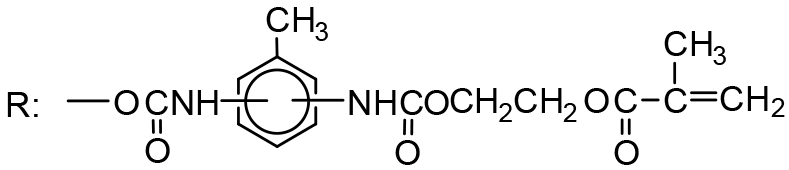

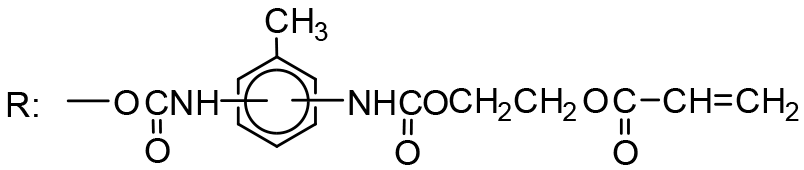

TE Series / Terminal Acryl Group Polybutadiene Urethane Bond

The TE Series is a polybutadiene acrylate resin with (meth) acryl groups attached to both ends of either polybutadiene or hydrogenated polybutadiene via a urethane bond. Because of the reactivity of the (meth) acryl groups, this series can be used in various compositions such as for adhesives and paints.

| Products |

Viscosity (Poise/45°C) |

Acryl equivalent (g/eq) |

| TEAI-1000 |

2500~4000 |

1200~1600 |

| TE-2000 |

1000~3000 |

1600~2300 |

Principal Uses

Adhesives, UV curable resins, electrical insulating materials, cast resins

Structural Formula

TE-2000

TEAI-1000

List of Properties

|

Properties |

| Terminal structure |

Modification of olefin |

Mn |

1,2Vinyl (%) |

Viscosity (Poise/45°C) |

Tg (°C) |

| B Series |

B-1000 |

H |

None |

1,200 |

89 |

10 |

-44 |

| B-2000 |

H |

None |

2,100 |

90 |

62 |

-29 |

| B-3000 |

H |

None |

3,200 |

90 |

210 |

-21 |

| BI Series |

BI-2000 |

H |

Hydrogenation |

2,200 |

<7 |

60 |

-51 |

| BI-3000 |

H |

Hydrogenation |

3,300 |

<7 |

180 |

-44 |

| G Series |

G-1000 |

OH |

None |

1,400 |

91 |

75 |

-25 |

| G-2000 |

OH |

None |

1,900 |

91 |

135 |

-19 |

| G-3000 |

OH |

None |

3,000 |

91 |

310 |

-15 |

| GI Series |

GI-1000 |

OH |

Hydrogenation |

1,500 |

<7 |

105 |

-44 |

| GI-2000 |

OH |

Hydrogenation |

2,000 |

<7 |

165 |

-42 |

| GI-3000 |

OH |

Hydrogenation |

3,100 |

<7 |

315 |

-37 |

| TE Series |

TEAI-1000 |

Urethane acrylate |

Hydrogenation |

2,000 |

<7 |

3,000 |

-14 |

| TE-2000 |

Urethane methacrylate |

None |

2,500 |

88 |

1,500 |

-9 |

| JP Series |

JP-100 |

H |

Epoxidation |

1,300 |

>70 |

220 |

-16 |

| JP-200 |

H |

Epoxidation |

2,200 |

>70 |

1,000 |

-7 |

* Physical properties are shown as representative values.

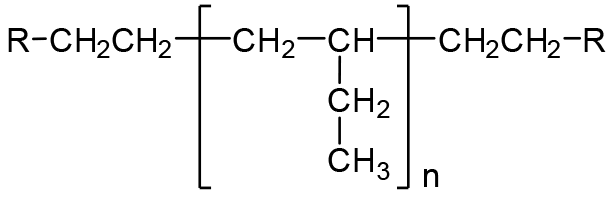

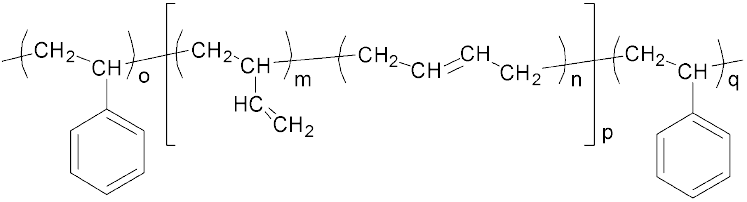

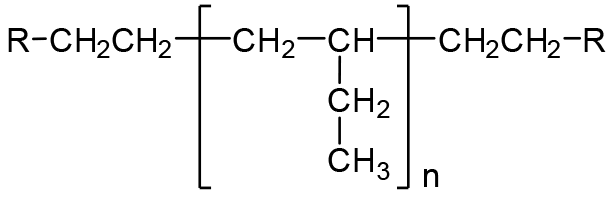

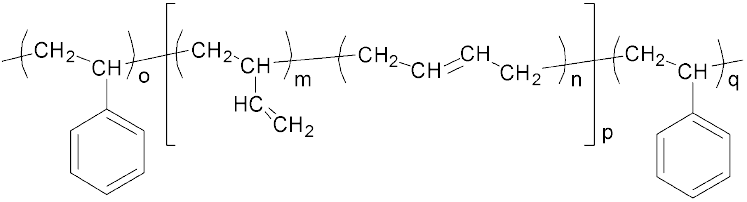

1,2-SBS (Styrene/Butadiene/Styrene)

produced by NIPPON SODA

By using Nisso’s proprietary technology, we are able to manufacturer a Styrene/Butadiene/Styrene block co-polymer (SBS) with high 1,2-vinyl content. Nisso SBS can offer extremely good crosslinking when combined with Nisso PB, but also works well as a standalone product. The high crosslinking density leads to improved heat resistance (increased Tg), elasticity, solvent resistance, and lower Dk and Df.

Principal Uses

Co-crosslinking agent, resin modifiers, electrical insulating agents, general rubber goods, adhesives

Structural Formula

| 1,2-SBS |

Contents

(wt%)

o/p/q |

Mn |

1,2-Vinyl

ratio(%)

m/(m+n) |

Viscosity

(P@45°C) |

| Solid type |

25/50/25 |

26,000 |

≧90 |

- |

| Liquid type |

10/80/10 |

5,000 |

≧90 |

1000 |

Solid Type

Solid Type Liquid Type

Liquid Type

Solid Type

Solid Type Liquid Type

Liquid Type